Understanding Your Tractor Protection Valve (TPV)

Before starting, understand the TPV's critical role. It's a safety device within your trailer braking system. Its primary function is to maintain air pressure in the trailer's brakes even if the trailer disconnects unexpectedly from the tractor. This prevents runaway trailers, a serious safety hazard. Regular TPV checks are essential for safe operation, comparable to routinely checking your car's brakes. Don't underestimate its importance! A faulty TPV puts lives and property at risk. For more detailed information, check out this helpful guide: TPV Testing Guide.

Gathering Your Tools

You'll need minimal equipment: an air pressure gauge (to measure air pressure in your system) and, optionally, a helper (for an extra set of eyes). That’s it! This test is straightforward and doesn't require extensive tools.

Step-by-Step TPV Testing Guide

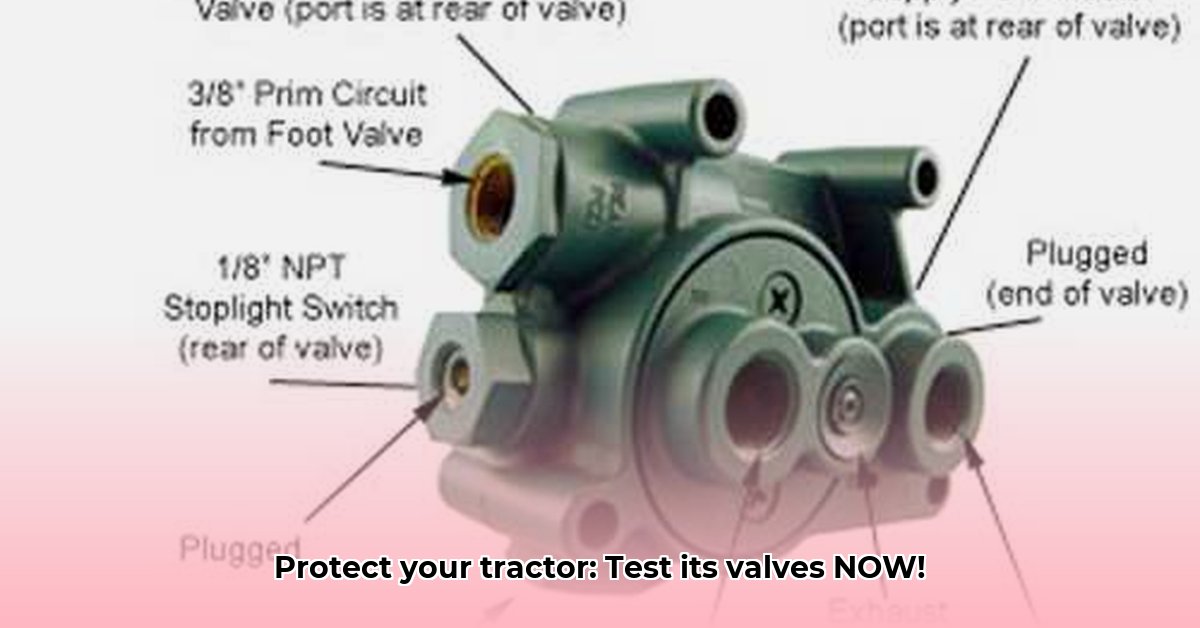

Follow these steps for a thorough TPV test. Remember: safety is paramount. Always consult your tractor's manual for specific instructions and diagrams.

Safety First! Always engage the parking brakes on both your tractor and trailer. Then, carefully disconnect the trailer's air lines. Safety is the top priority; never skip this step.

Air Pressure Check: Use your air pressure gauge to verify sufficient air pressure in your tractor's air tank. Low pressure invalidates the test; address this before proceeding. This is your "pre-flight check."

TPV Functionality Test: Depress the tractor's service brake pedal firmly. You'll see a slight drop in the tractor's air pressure. Crucially, the trailer's braking system air pressure must remain stable. A significant drop indicates a malfunctioning TPV needing immediate attention.

Reconnection and Verification: Carefully reconnect the trailer's air lines. Confirm that air pressure has returned to normal levels in both the tractor and trailer.

Record Keeping: Maintain detailed records of all TPV tests. Document the date, results (pass/fail), and any observations. This documentation is crucial for maintenance scheduling and demonstrates compliance with safety regulations and best practices. This simple step reduces liability and assists in proactive maintenance.

Interpreting Your Results

A successful test shows stable trailer air pressure during tractor brake application, indicating a functioning TPV. However, a pressure drop signifies a faulty TPV requiring immediate replacement. Don't delay repairs; a working TPV is non-negotiable.

Maintenance and Prevention

Regular inspections and testing are vital for preventing TPV issues. The testing frequency depends on tractor usage, but monthly checks are recommended. Early problem detection prevents major issues. Proactive maintenance is far cheaper and safer than reactive repairs.

Regulatory Compliance and Best Practices

Regular TPV testing isn't just about safety; it's often a legal requirement. Familiarize yourself with applicable regulations to avoid fines and legal complications. Compliance is not optional; it's a requirement for responsible operation.

Why TPV Testing is Critical

A functioning TPV prevents costly accidents, protecting drivers, cargo, and the public. Regular testing is a small investment with significant returns in terms of safety and avoidance of costly repairs. Don't underestimate the importance of this simple yet crucial procedure. Remember, safety always comes first.

Key Takeaways:

- Regular TPV testing ensures safety and regulatory compliance.

- Consistent testing procedures minimize accident risks and potential fines.

- Understanding TPV function is critical for safe operation.

- Standardized testing ensures thorough and effective results.

- Detailed test documentation is essential for audits and legal purposes.